During the preparation phase the authorized employee must investigate and gain a complete understanding of all types of hazardous energy that might be controlled.

Loto lock box procedures.

If maintenance service of the equipment will occur on different shift and with different mechanics the mechanics on the leaving shift will meet with the mechanics on.

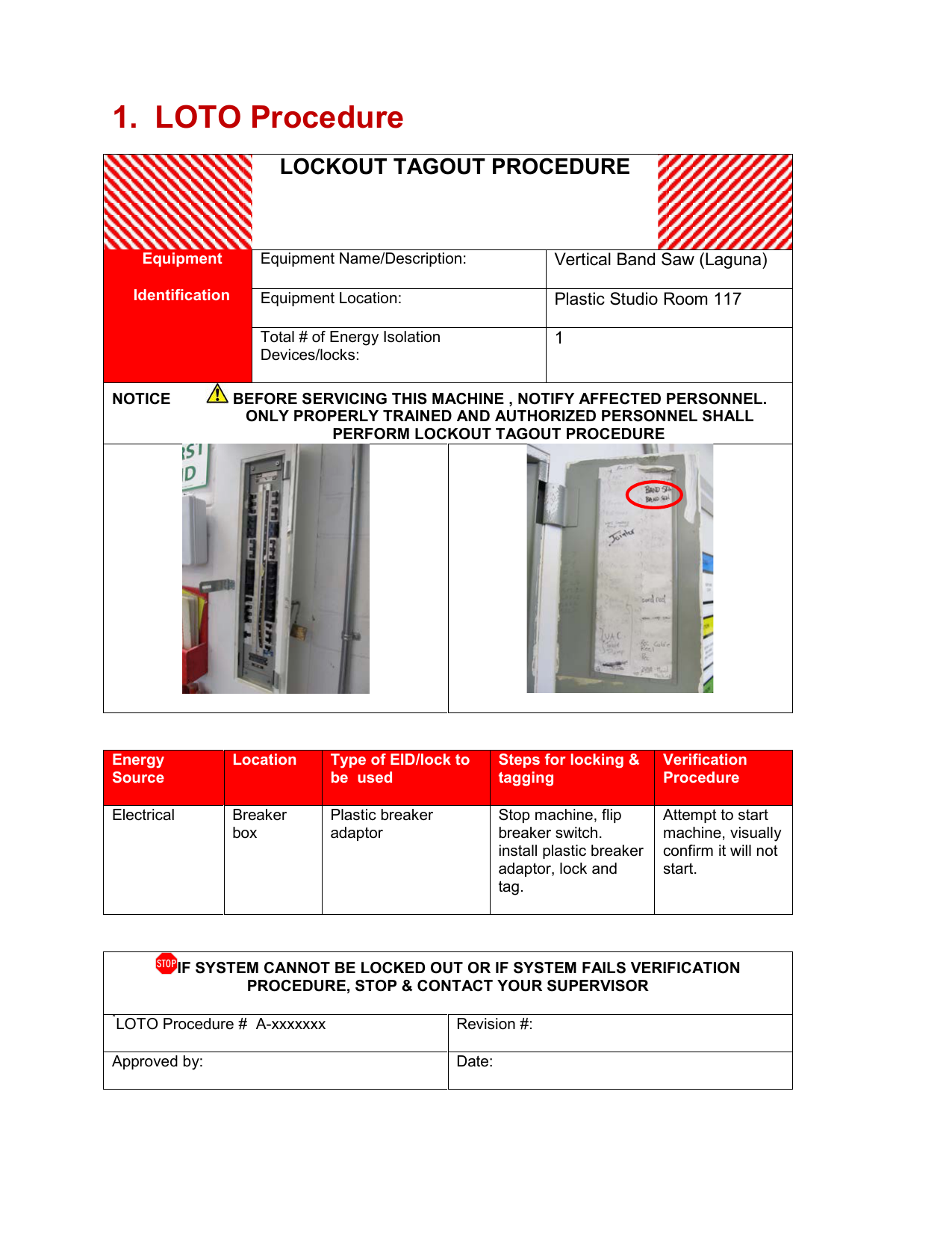

Loto safety lockout tagout safety procedure.

How can we get better.

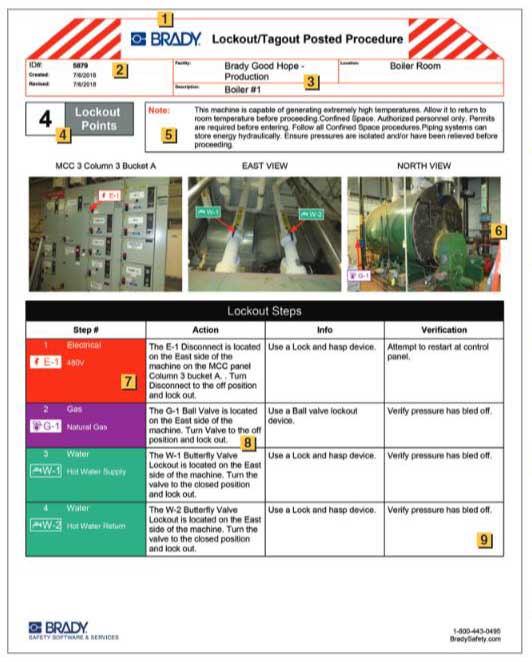

A sample lockout tagout procedure a good lockout tagout procedure at a minimum should contain the following elements.

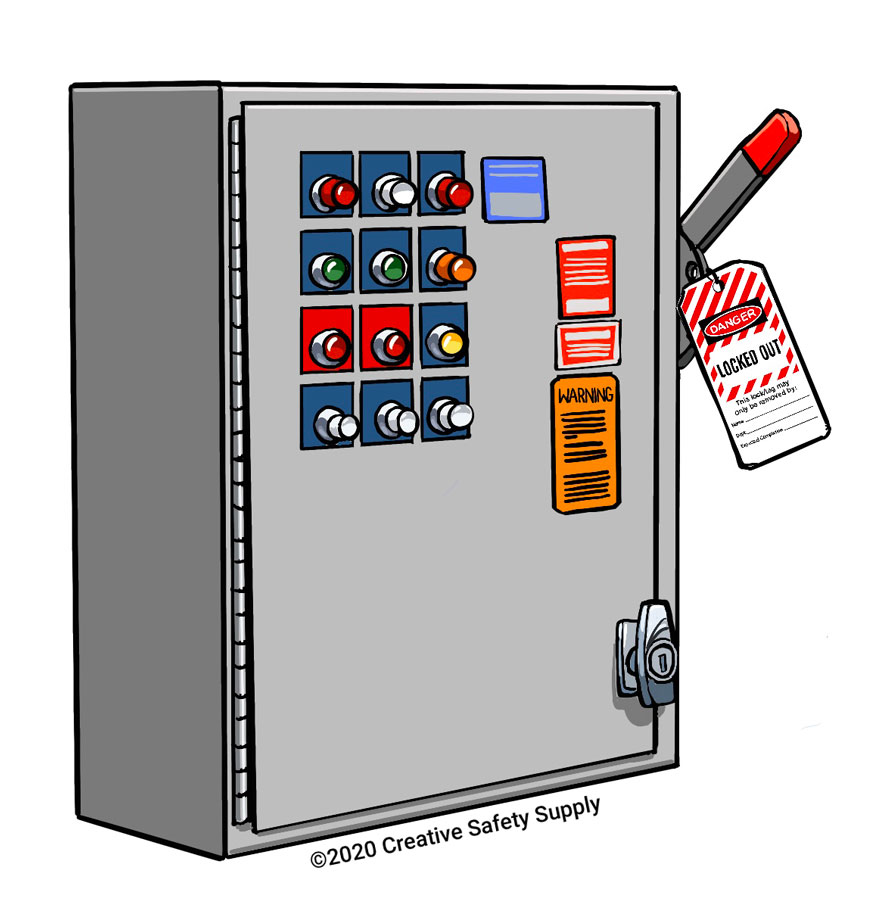

A lockout tagout loto procedure is a safety system used to prevent accidental or unauthorized access to electrical power sources that are undergoing maintenance or other work.

What are some of the common mistakes we make with loto.

What can we do at this workplace to ensure proper lockout tagout is used.

All maintenance personnel shall be provided with a good lock.

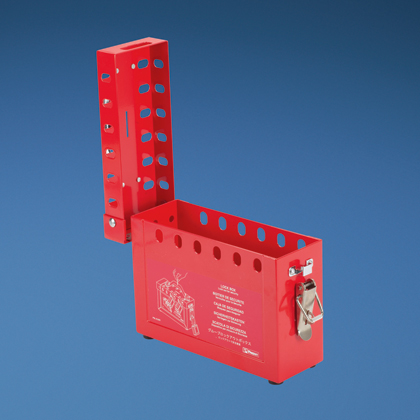

Lockout form a preprinted form to fill out for group loto procedure to document and communicate isolation and repair status lockout tagout specific practices and procedures to safeguard employees from the unexpected energizing or start up of machinery and equipment or the release of hazardous energy during service or maintenance activities.

Each worker shall have the only key to the lock.

Lockout lock and orange group lockout master lock tag to the group lockbox.

The lock shall have the individual workers name and other identification on it.

Lockout tagout lockout tagout interactive training program.

Is the first lock to be applied on the group lockbox and the lock must stay in place for the duration of all work.

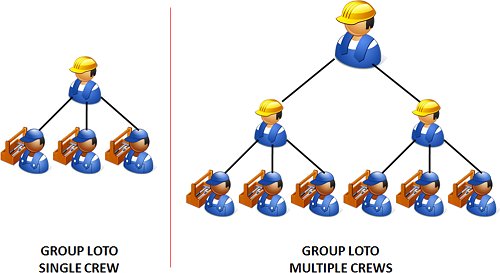

Whenever servicing and or maintenance is performed by a group of employees the employer must develop and implement an energy control procedure that provides authorized and affected employees with the same level of protection as a personal lockout or tagout device.

A multi lock hasp is then placed on the lock box and all other employees performing maintenance service on the piece of equipment lockout tagout the box of keys.

With this secured process all individuals working on the same circuit or equipment have individual locks that they secure onto a disconnect device before working on the system.

The next step of the lockout tagout procedure is to isolate the machine or equipment from any source of energy.

The lead authorized worker must be the first to lock on and the last to.

What are lockout tagout procedures at this worksite.

Grain handling safety.

Group lockout master lock.

What can we do today to demonstrate proper lock out tag out try out techniques.